|

Marine

-

Cranes

-

Container Handling

Equipment

-

Yard Tractors/Forklifts

-

Generators

-

Tugs - Small Vessels,

Pleasure Craft

-

Outboard - Inboard

Motors

n

n

n

Diesel Engines are use in Marine, Agriculture, Construction, Generators,

Pumps, Trains etc.

Petroleum Technologies LLC 's Vitalizer

is specifically engineered to work best on heavy-duty mechanically injected diesel equipment.

The diesel fuel burned by machinery used in

Marine, Agriculture, Construction, in Generators, Pumps, Trains, etc. can be 6 times dirtier than the fuel used by trucks

and buses. These types of engines burn fuel that may contain up to 10 times more sulfur.

Marine Container cranes: 7.5% Fuel Savings

Marine Contaner Handlers Alamo Terminales Maritimos, Costa

Rica, Fuel Savings 9%

Fishing Vessels Pipi Mali and Pipi Velliki 600 Hp Caterpillar

Engines Fuel Savings 13%

Passenger Vessel1,100 hp engine fuel savings 12%

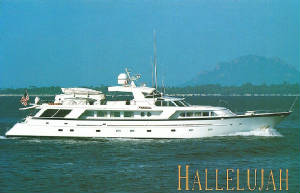

"The Normal fuel consumption on this 117' Yacht is 781

gals, per/day; after Activator we averaged 701 gals, per/day-a 10% savings. There is a much cleaner exhaust; and visibly

less carbon buildup on the hull."

YACHT HALLELUJAH

Result of

3rd chance to test this product:

- The normal fuel consumption on this

117' Motor Yacht is 781US gallons/day. This Trans-Atlantic Crossing averaged 701g/d. That is a 10.2% reduction

in normal fuel consumption. This is over the fuel savings hope for.

- The other thing of interest is a

much cleaner exhaust. There is visibly less carbon build-up on the hull.

The only thing these changes

can be attributed to would be the "Vitalizer", Advanced Fuel Performance Technology by Petroleum Technologies

LLC . (Captain Ted Sputh

Master M/Y Hallelujah

HYDRO-FOIL 180 PASSENGER SHIP,

30 KNOT SPEED - FUEL SAVINGS 17%

Vessel has two 1,100 hp engines----Zadar. Croatia

Conclusions drawn from testing on one of a pair of Yamaha 200 H.P. outboard engine.

The VITILIZER performed the following functions:

- Engines

had completed 461 hours before fitting. After 38 hours additional running the test engine progressively attained 16.62%

increase in fuel economy after final service in comparison with its running twin.

- All carbon

had been cleaned from piston head, combustion chamber and exhaust ports.

- Bore glaze

was considerable reduced and cross hairs in the bore were showing.

- Ignition

knock, standard in these engines was eliminated.

- Spark plugs

cleaned up and stayed clean.

- Engine

could be turned for more efficient operation and further fuel saving.

- Observation

with bore scope in crankcase showed much improved spray pattern from carburetors.

- Reduced

visible idling exhaust emissions considerably.

- Engine

ran cooler - verified by independent instruments.

- Carburetor

internals were completely clean compared with other motor.

The full detailed

report was prepared from continuous checks every approx. 10 hours and the engines had normal services as required during this

time. (Pauls Marine Diesel Engineering PTY LTD))

|